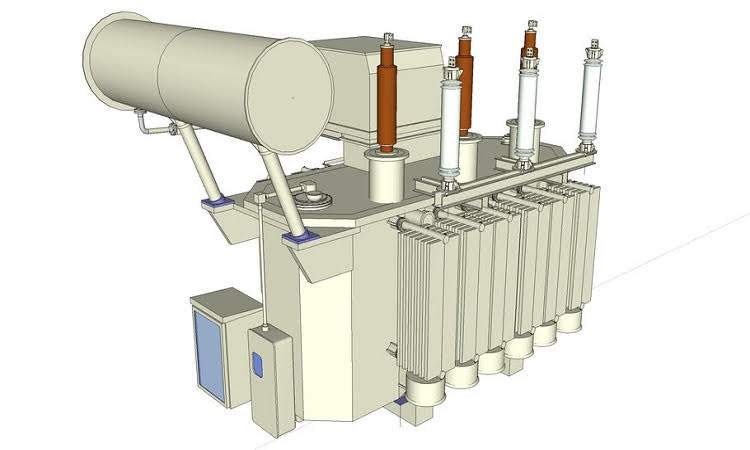

Top 3 Reasons For The Failure Of Power Transformers

Failure in power transformers occurs because of low-quality materials, lack of craftsmanship, and vulnerable design. When you want to buy big-ticket items, Power Transformers are at the top. So, the failure occurs due to prematurity and thus leading to horrifying conditions.

Power transformer manufacturers India offers high-quality and reliable products at affordable prices to benefit consumers.

When the damages occur in Transformers, it exceeds the cost of a replacement, so better you can replace it instead of repairing it. The additional cost because of damage includes damaged credibility, regulatory fines, civil lawsuits, and loss of production time. Still, many industries, factories, and power plants suffer from these problems.

Other facilities like small-scale industries hopefully learn from these mistakes. The failure analysis experts investigate Transformer’s death immediately, making it easy for some facilities to understand the problem earlier.

This job of failure analysis experts is similar to the detective job is done by experts. They come up with the ideas or solutions to the problems during the crime scene and determine what went wrong and who is at fault, either the Transformer or others.

Customers always find it difficult when Transformers show some error or failure since it has been one year after installation. Some experts and analysts try to find what went wrong, and it is evident that you get what you pay for, so it is ultimately essential to know about the Transformers before buying them.

Facilities managers, specific Electrical engineers, plant engineers, and general contractors learn a lot from dissecting numerous Transformer after failures. Hence these experiences make them experts and specialists in the particular field.

The experts say in most cases, the failure is significant because of premature Transformers or inadequate design structure. Master electricians or experts like expert say that Transformer’s failure occurs very rarely. Still, when the failure occurs, it turns out to be a devastating failure leading to high costs due to the damage caused.

Expert says that you must buy cost-effective equipment, not cheap, because the cheaper one can cost you more in the long run, especially if they are essential to your business strategy or data centers. Then the additional amount invested for a better unit denotes inexpensive protection.

The master electrician admits that it becomes tough to convince a customer who does not confront these costs. Still, the proof of his confidence fabricates in what he had seen in the failure of infinite Transformers.

Expert says that the most attractive factor in the long run of a transformer is the attention to detail in the manufacturing process, the quality control, and the level of craftsmanship. These factors are often seen in all the manufacturing processes, including Transformer’s manufacturing process.

Expert says his opinion that experience and pride of work went away when machines started to build Transformers. This machine build-up Transformer happens only when the manufacturers lack experience and often depend on highly automatic processes. A machine always can’t find defects.

While searching through his files, expert came up with an example.

Expert continued by saying that if you know that a replacement Core and coil would run for a considerable amount leaving the rigging and installation cost, which would account for some amount, you must demand the manufacturer to witness the technicians dissecting the Transformer. This tip of expert would intensely work.

Expert found that the fault at the crossover was due to opposite polarity windings that passed through a guide tube. This fault was found while cutting the insulation and epoxy with a gasoline-powered concrete saw. Expert added that the fault was because there was no separation among the wires. The fault would not have occurred if at least 1.5 inches of space or void between the wires.

Johns says that before the resin was baked and poured in, it was an evident example of someone failing to fix and inspect the area, and it led the manufacturer to supply a new Coil and Core. However, the client was not ready to pay the cash outlays.

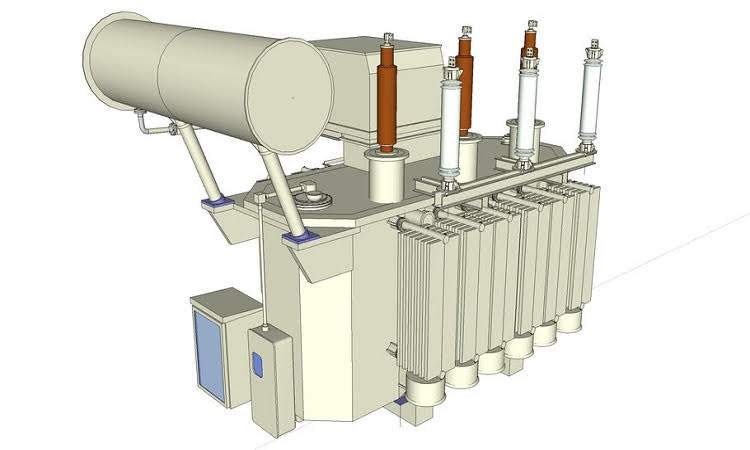

A VP of Engineering for electric service corporation (ELSCO) Alan Ober says, nowadays they put the Transformers in tight spaces or on the top of the building where you will need cranes to replace the Transformers. Alan adds that the cost will be twice the amount to swap or replace it when the Transformer is mounted on the top of the roof. EBSCO is a Cincinnati-based Transformer manufacturer. Alan Ober had gone to many sites to see the installations of Transformers.

How long a transformer will last depends on the craftsmanship, but these days, this attention to describing the manufacturing features has been taken over by automatic machines.

Materials used in the manufacturing process

Power transformer manufacturers India considers the demands of consumers to produce highly preferable products. Materials come in the next place of craftsmanship. The material used in the manufacturing process is a significant factor in the construction of Transformers. According to expert, the type of insulating material we use and the perfect wire we use to create a significant difference in the long run of the Transformer.

Expert says that it is essential to know the iron core material used in the Transformer. The best of all core materials is pure original magnetic silicon steel (opposed to recycling), and also it is better to use the thin core Steel pieces.

Power transformer Manufacturers India commonly uses M6 Steel, which has a thickness of 0.014 inches per piece. Another Steel which is M3, has a thickness of 0.009 inches per piece, and hence it covers the same volume or area since M3 is thinner than M6, so it is better to use M3 as a core Steel.

Alan Ober says that the Transformer fails due to high heat. Transformers waste vast amounts of energy by creating heat. The life of the insulation becomes short, leading to the failure of the Transformer.

Conclusion

Thus, in this article, we have seen the top three reasons for the failure of Power Transformers. You must consider all the three reasons before installing a transformer, and hence it can protect your Transformer before failure.